WAREHOUSE LOGISTICS OPTIMIZATION

Warehouse logistics optimization plays a vital role in enhancing operational efficiency and productivity in modern supply chains. Among the various components of warehouse logistics, forklifts play a critical role in material handling, transportation, and storage operations. Optimizing forklift activities can lead to significant improvements in overall warehouse efficiency, reducing costs, and ensuring timely order fulfillment.

PROBLEM: OPTIMIZING FORKLIFT OPERATIONS

Forklifts are essential tools in warehouse logistics as they facilitate the movement and transportation of goods within the facility. Forklift optimization focuses on streamlining forklift operations to minimize idle time, reduce travel distances, and maximize productivity.

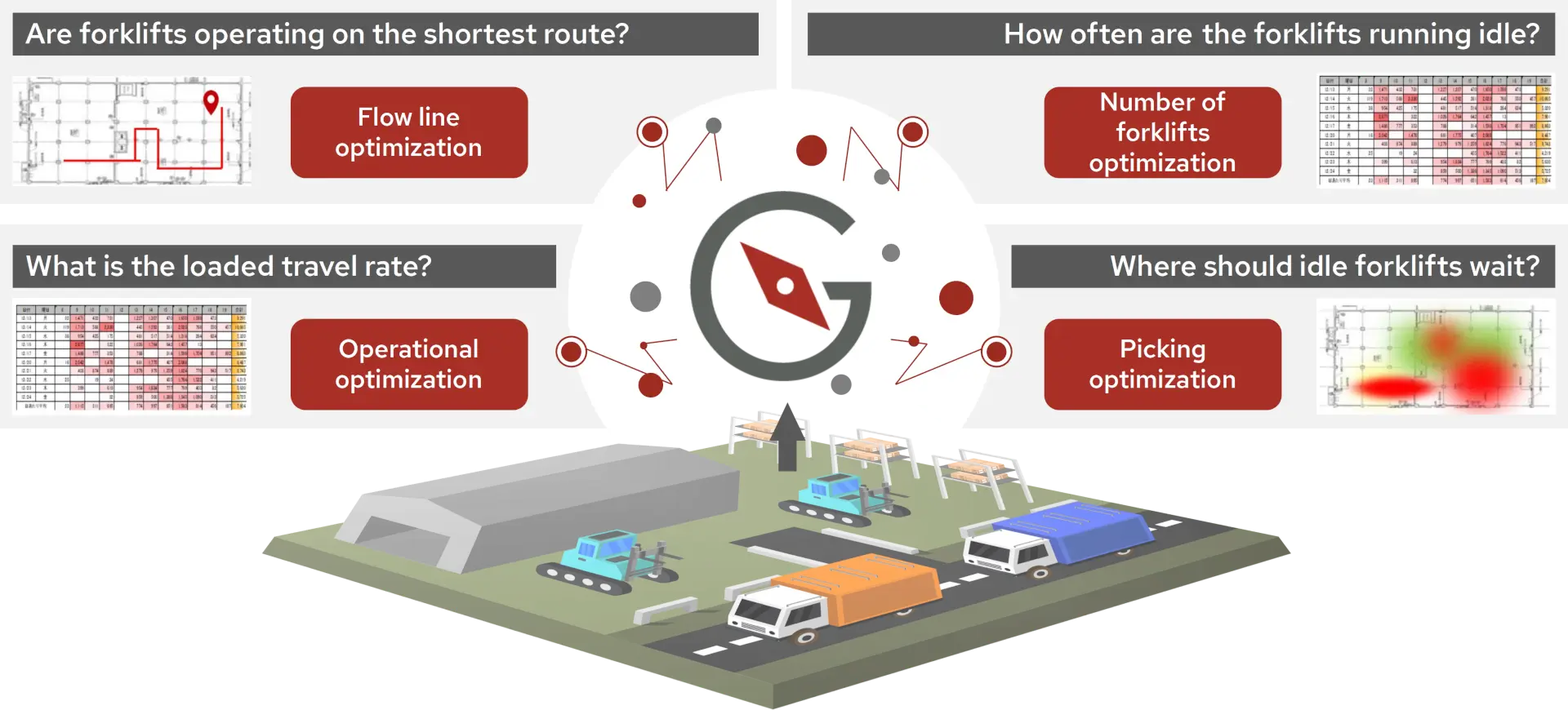

Several problems need to be solved when optimizing forklift operations in warehouse logistics, as shown in the graphic below.

To optimize forklift operations in warehouse logistics, businesses can employ various strategies, including:

- Warehouse layout optimization: Analyzing the facility layout to minimize travel distances, reduce congestion points, and create efficient traffic flows for forklifts.

- Route optimization: Implementing advanced routing algorithms to calculate the most efficient paths for forklifts, considering factors such as load weight, pick-up/drop-off locations, and real-time traffic conditions.

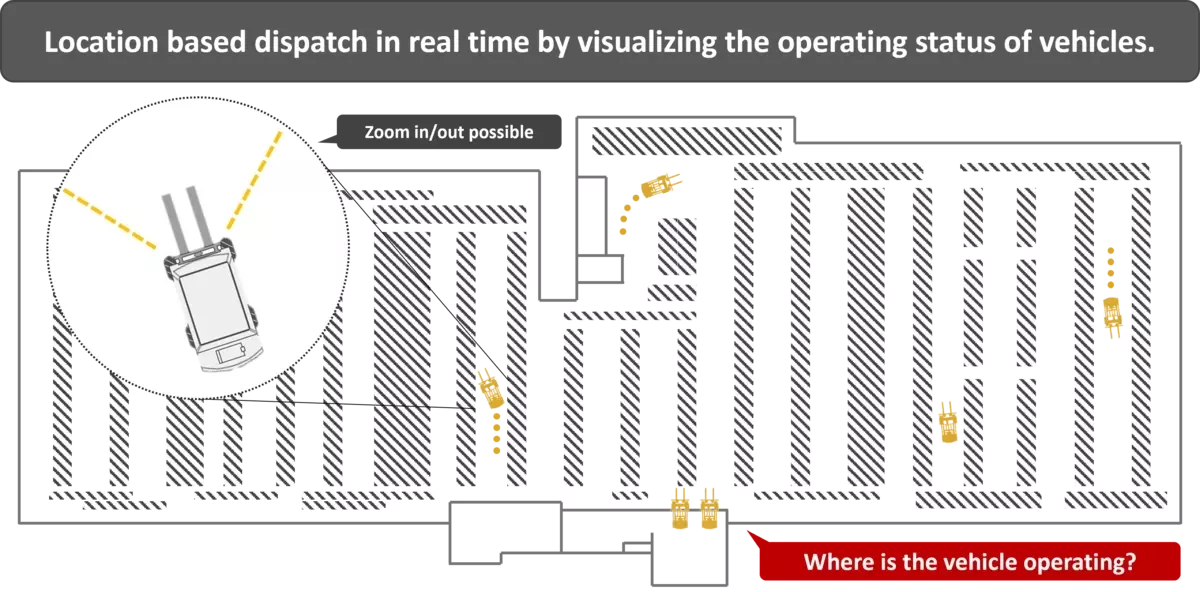

- Real-time tracking and monitoring: Utilizing technologies such as indoor positioning and RFID to track forklift movements, monitor their performance, and identify areas for improvement.

- Automation and robotics: Integrating automated guided vehicles (AGVs) or robotic forklifts that can operate autonomously, improving efficiency, and reducing human error.

SOLVING IT WITH GuideNS™

We have developed GuideNS™, a Visual-Inertial SLAM (Simultaneous Localization and Mapping) based navigation system for forklifts and autonomous robots. Our system consists of smart edge devices and a cloud-based backend with application programming interfaces, which enable logistics operators to collect real-time localization and visualization of their material handling assets to improve productivity and safety.

Based on the real time navigation data provided by our solution above, we empower the client to implement all of the strategies mentioned above for improving the efficiency of forklift operations. In addition to optimization considerations, our data can also be used for improving the safety of forklift operations and reduce the number of accidents.

Some examples of information that is available on our web browser based visualization & analytics dashboard are shown below. The images below are for illustration purposes only and do not contain any customer specific data.

THE GuideNS™ ADVANTAGE

Traditional indoor positioning is inadequate in GPS-denied environments due to poor accuracy, interference from metal structures, reliance on antennae, and limited travel distances. Further the poor data quality, high cost and difficulty of deployment of traditional solutions make them prohibitive compared to our solution.